|

|

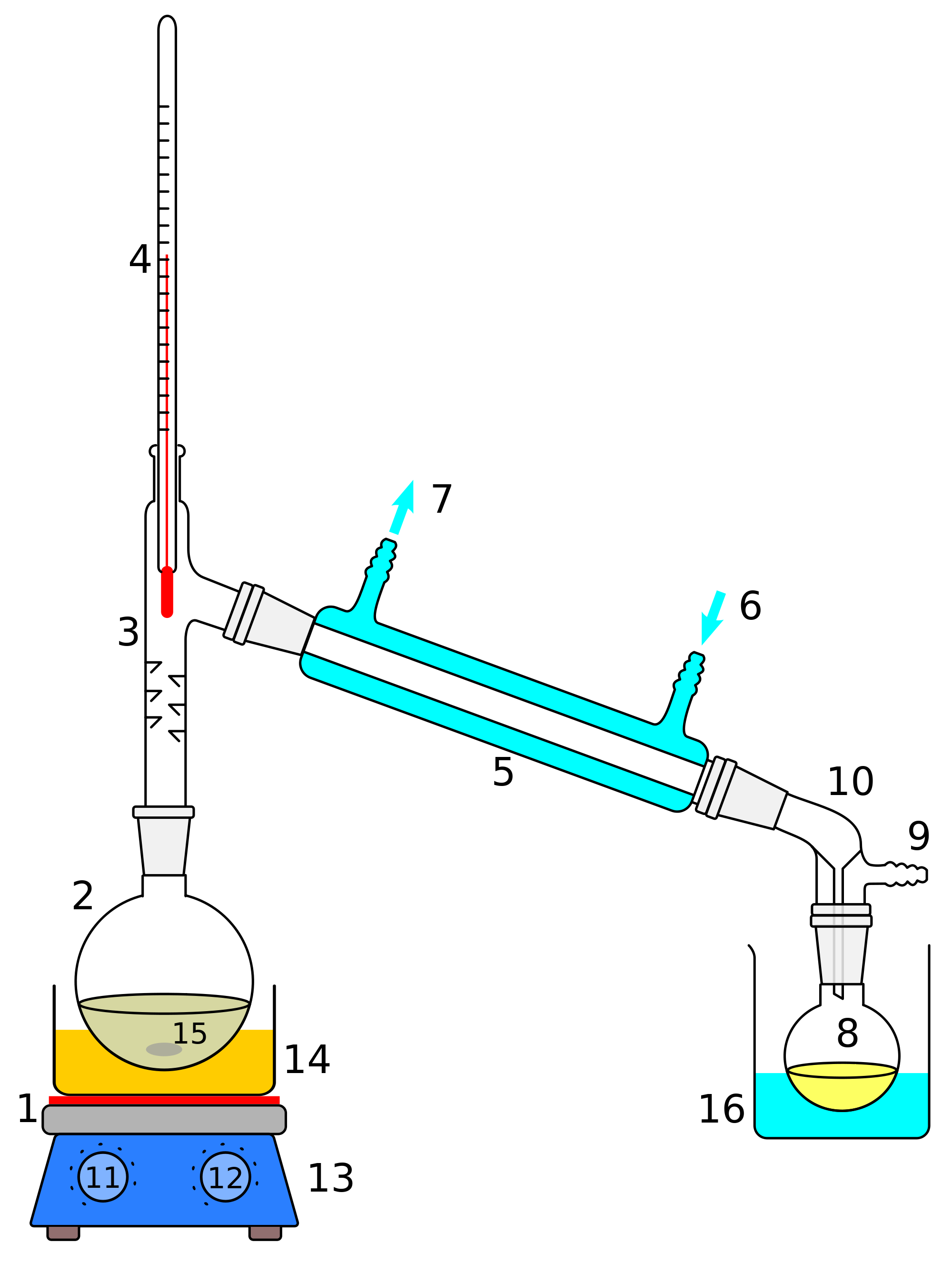

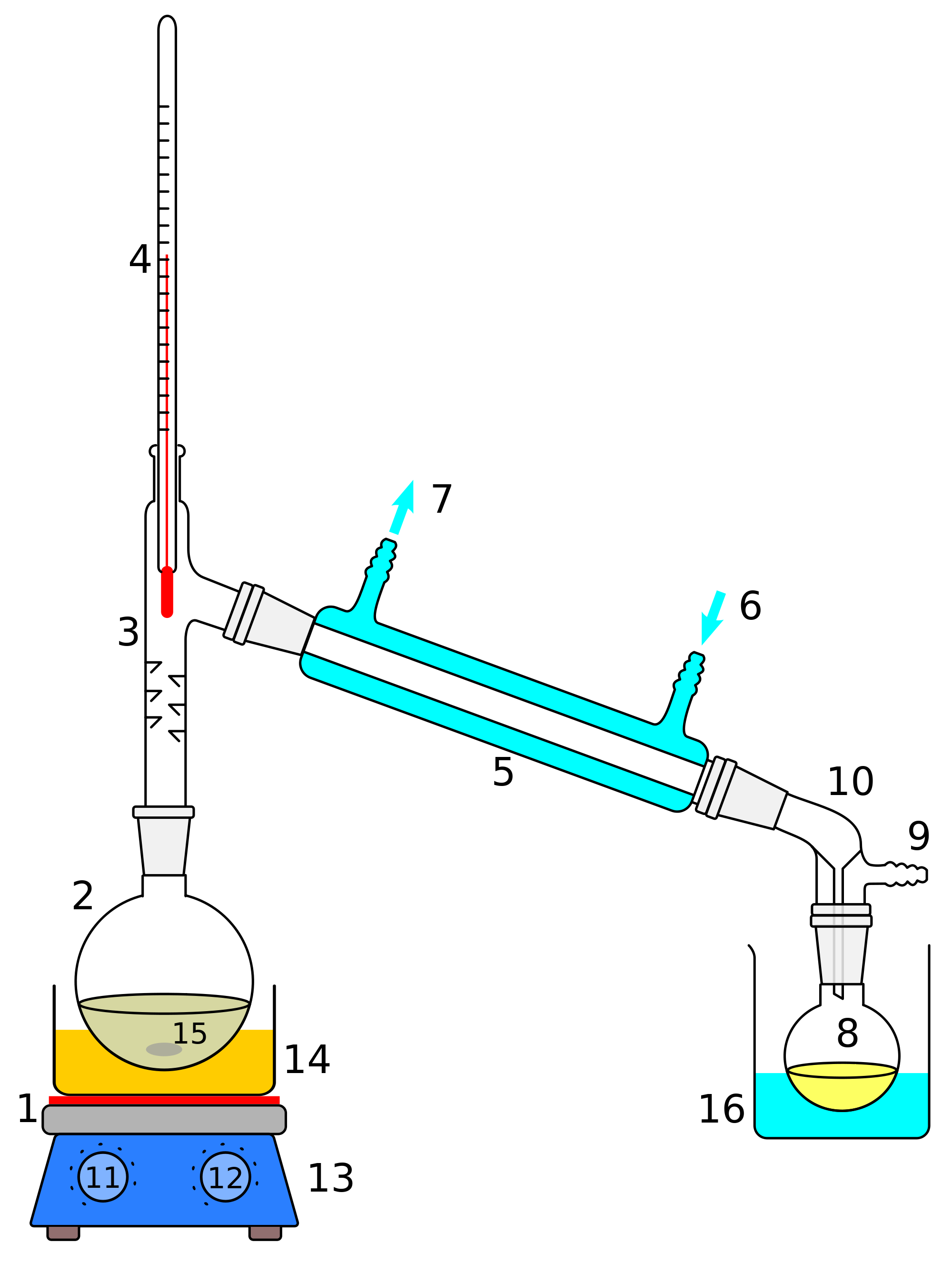

In simple distillation,

all of the material which is evaporated

and then condensed (the distillate) is collected together

as a single fraction. Labeling code: (1) Heat source. (2)

Still pot. (3) Still head. (4) Thermometer. (5) Condenser.

(6) Cooling water

in. (7) Cooling water

out. (8) Distillate receiver. (9) Vacuum adapter. (10)

Still receiver. (11) Heat controller. (12) Stirrer

controller. (134) Stirrer/hot plate. (14) Heating bath.

(15) Stir bar. (16) Cooling bath. Click

here for a larger version. |

|

|

|

|

|

A still for making moonshine (illegal hard liquor) uses

simple distillation. The silver cylinder is the still pot

(which is heated by a wood fire), the copper tube is the

condenser, and the green barrel is the still pot.

Distillation of legal liquor is conducted in a distillery. |

|

|

|

|

|

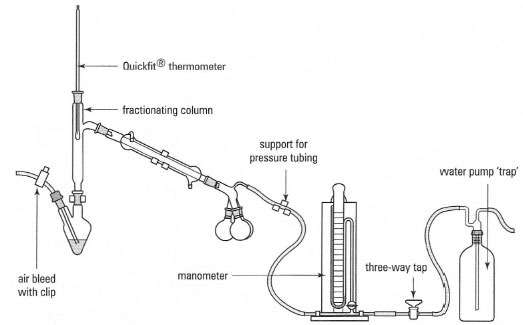

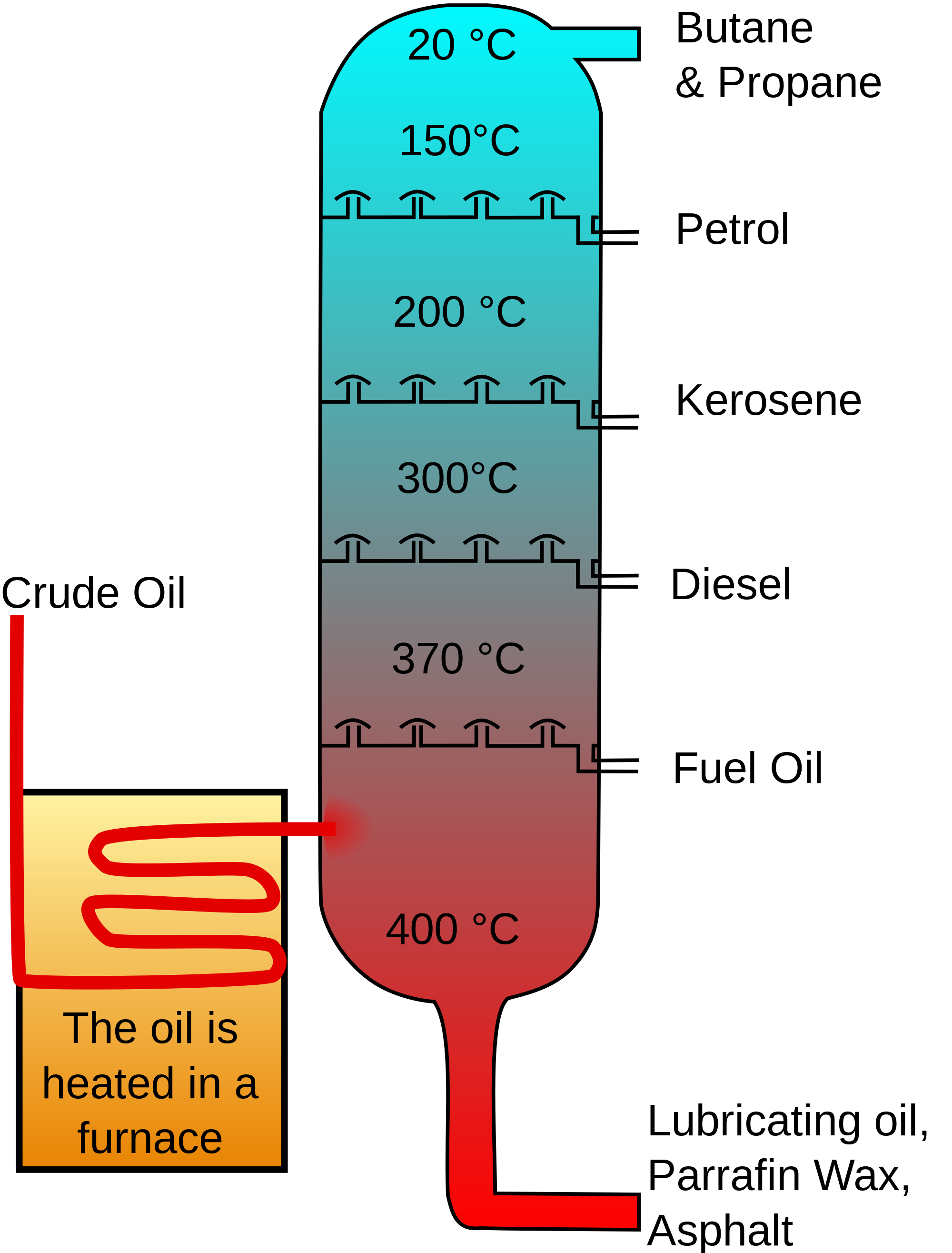

Fractional

distillation operates much like simple

distillation, except that the distillate is divided into

fractions. Each fraction might be a pure compound, or a

mixture with a different boiling

point range than other fractions. |

|

|

|

|

|

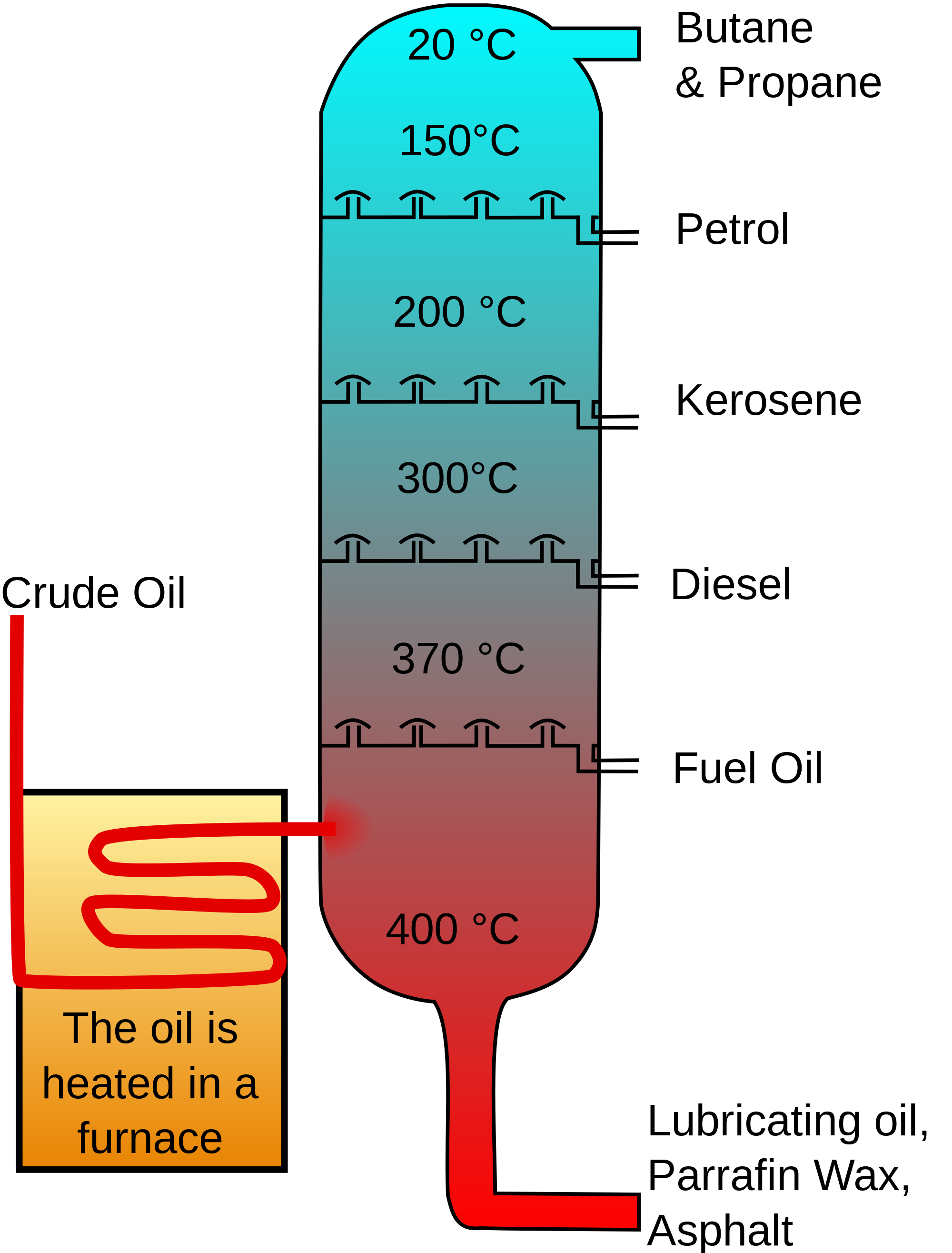

Diagram of a refinery's fractional

distillation column. An oil refinery uses fractional

distillation to separate crude

oil into material that have different boiling

point ranges. Gasoline,

composed mostly of C4 to C12 hydrocarbons,

is the fraction whose boiling

point range is about 40oC to about 200oC,

while

the kerosene/jet fuel fraction is composed mostly of C12

to C16 hydrocarbons

and has a boiling

point range is about 200oC to about 250oC. |

|

|

|

|

|

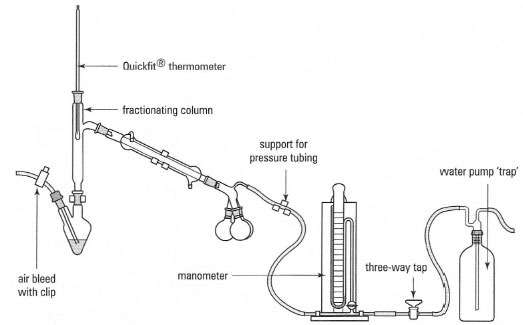

A rotary evaporator (rotovap) uses

simple vacuum

distillation to remove solvent

from a sample. As the ambient pressure is lowered, boiling

point is also lowered, so the solvent

evaporates more readily. |