Electrochemical capacitors, also known as supercapacitors, are energy storage devices like batteries, yet they can be recharged a hundred to a thousand times faster. Because of their enabling features, supercapacitors are replacing batteries and capacitors in an increasing number of applications. Supercapacitors are used in today’s smart phones to provide high intensity flash for the camera phones. In addition, their high power density and excellent low temperature performance have made them the technology of choice for back-up power, regenerative braking and whenever a high power is required in a short period of time. They also play an important role in the progress of hybrid and electric vehicles. However, the low energy density of the current supercapacitors is the main impediment to realizing the full commercial potential of this technology. This has triggered tremendous research efforts in order to develop new electrode materials that are capable of providing a huge amount of energy in a short period of time. In addition, the dramatic increase in flexible and miniaturized electronics has motivated the search for a new generation of energy stroage systems that are flexible, foldable and even twistable, can be miniaturized to the microscale and store large amount of charge per footprint. To address these issues, our research team is active in the following areas:

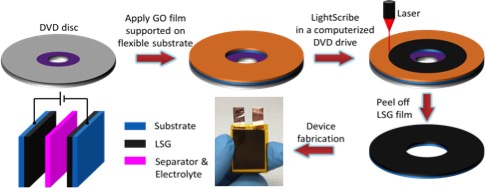

Graphene has garnered attention as a material for the next generation supercapacitors because of its outstanding mechanical, thermal and electrical properies as well as its chemical stability, extremeely large surface area and high theoretical specific capacitance of 550 F/g. A consumer grade LightScribe DVD burner is used for the direct writing of graphene films that can be used directly in supercapacitors without the need for binders or conductive additives generally used in conventional supercapacitors. This may lead to a new generation of rollable, bendable and even twistable supercapacitors.

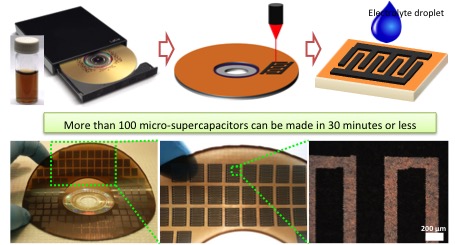

The demand for smaller electronic devices has spurred the miniaturization of a variety of technologies including enegy storage. Unfortunately, traditional methods for the fabrication of micro-supercapacitors involve labor-intensive and time-consuming lithographic techniques that have proven difficult for building cost-effective devices, thus limiting the commercial applications of micro-supercapacitors. Instead, we use a consumer-grade LightScribe DVD burner to produce graphene micro-supercapacitors over large areas at a fraction of the cost of traditional methods. No photomasks, post-processing or expensive cleanrooms required.

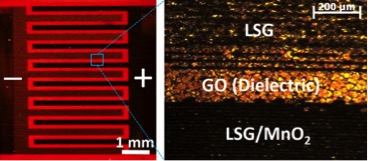

Battery users would like energy storage devices that are compact, reliable, and energy dense, charge quickly, and possess both long cycle life and calendar life. We demonstrate 3D high-performance hybrid supercapacitors and micro-supercapacitors based on graphene and MnO2 by rationally designing the electrode microstructure and combining active materials with electrolytes that operate at high voltages. These hybrid supercapacitors can store as much charge as a lead acid battery, yet they can be recharged in seconds compared with hours for conventional batteries.

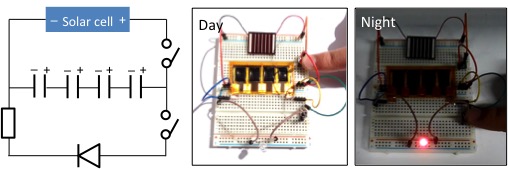

Supercapacitors can be combined with solar cells for storing huge amounts of energy during the day which can then be released at night for the operation of LEDs. Consideration is being given to use this opportunity for off-grid street lighting, thus saving enormous amounts of energy.

Poly(3,4-ethylenedioxythiophene) and other conducting polymers are promising materials for redox supercapacitors because they can be switched between several oxidations states. The performance of these materials depends on several parameters including surface area, electrical conductivity, environmental stability, etc. Nanostructuring of conducting polymers is an effective strategy to improve the charge storage capacity. Here, we are working on methods for the deposition of PEDOT nanofibers from the vapor phase without the need for hard templates or structural directing agents. This process results in high aspect ratio PEDOT nanofibers possessing a high conductivity of 130 S/cm and excellent capacitive performance.